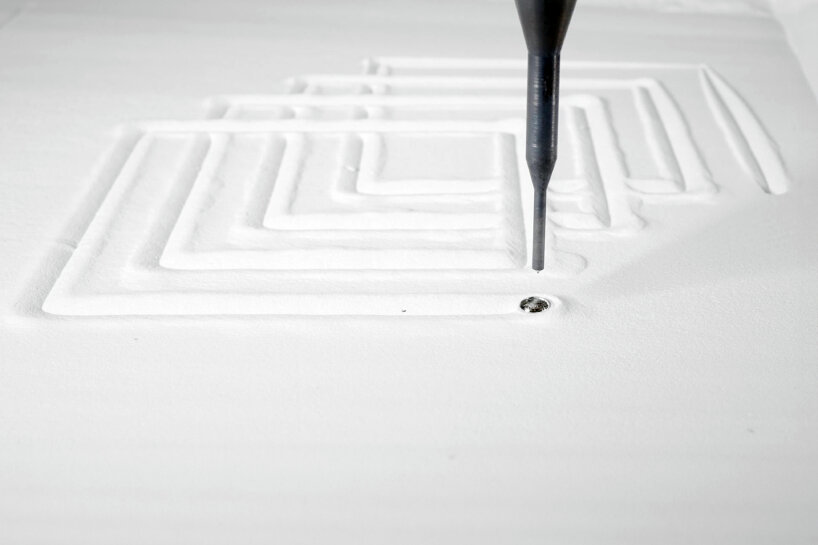

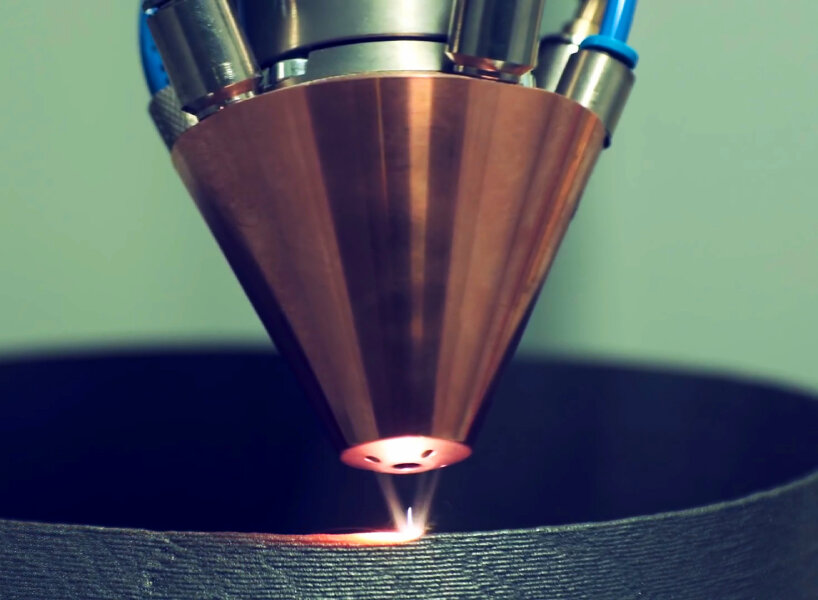

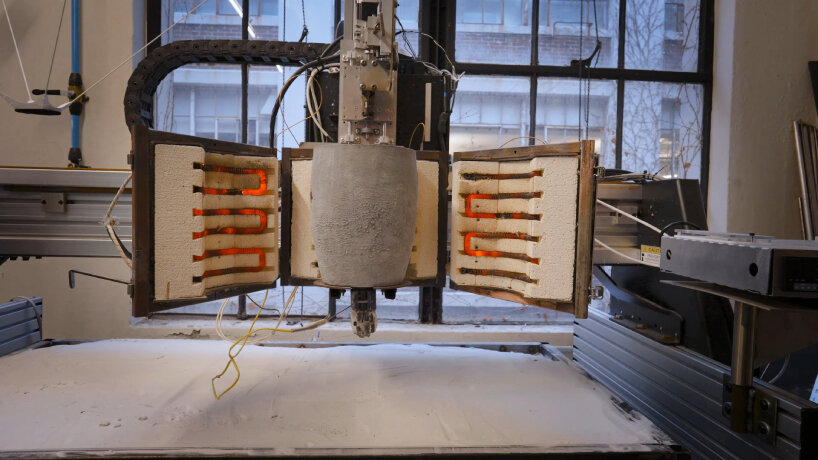

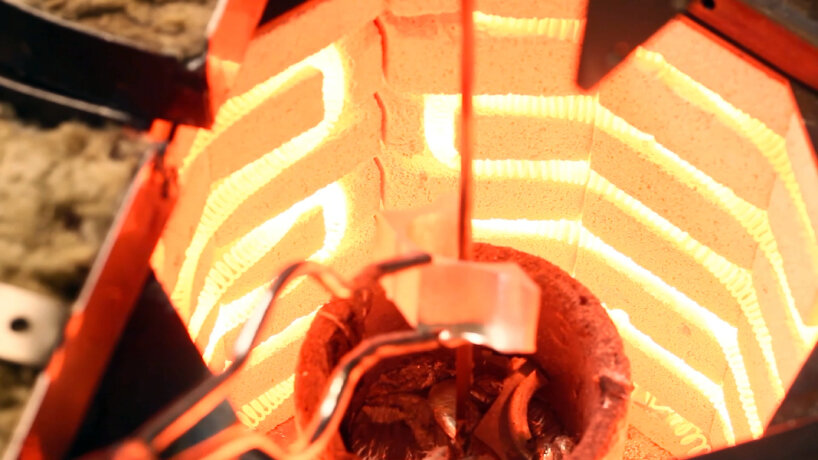

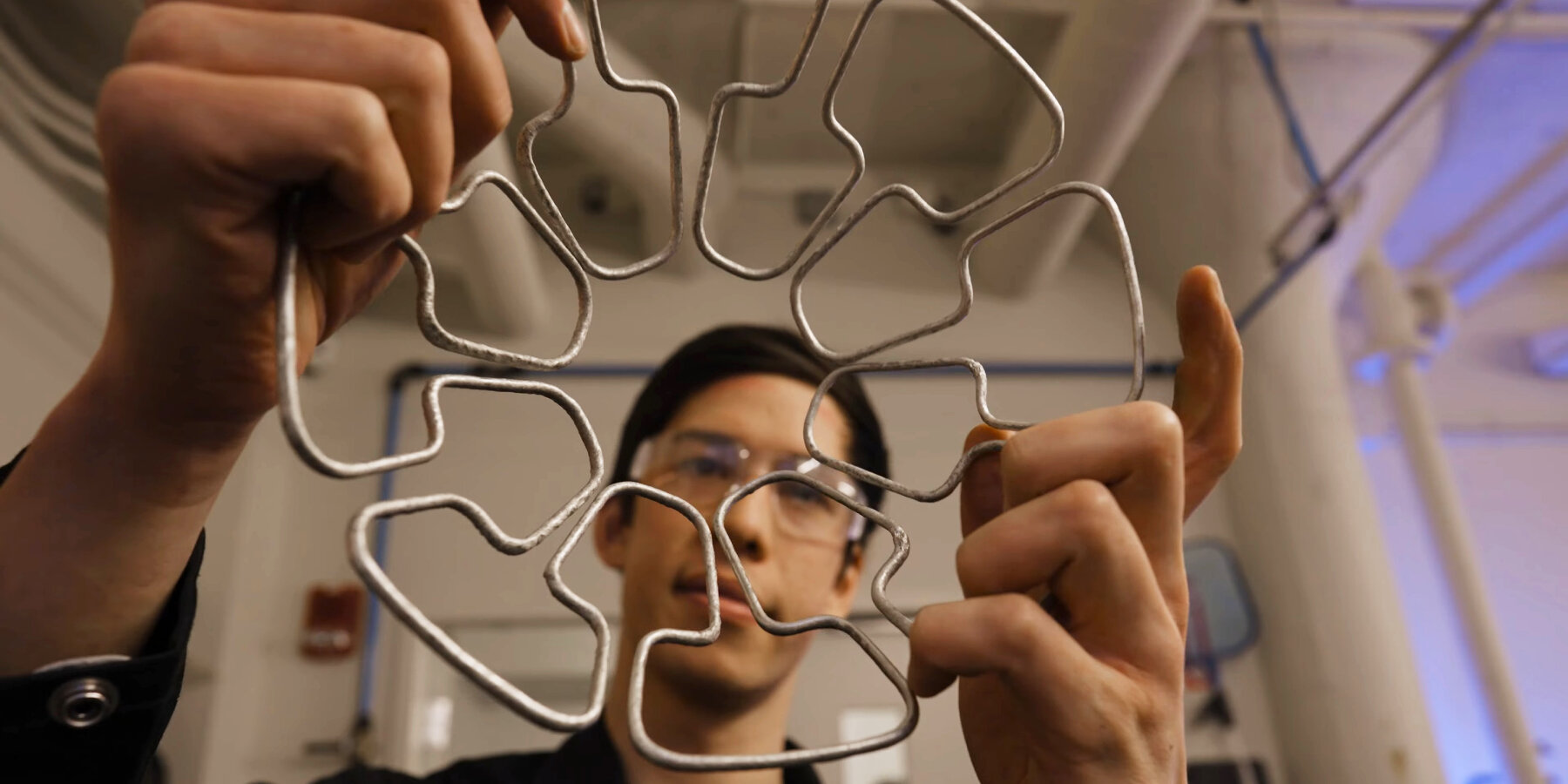

the new technique can make 3D printing objects faster with liquid metal

MIT researchers are working on refining the new technique

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

PRODUCT LIBRARY

creative studio bel&bel is ready to work on commission for selected riders who wish to own their rendition of shotaro kaneda’s akira bike.

connections: +440

mansory looks into the future of vehicles by hinting at a flying supercar named 'empower'.

connections: +530

plans have been announced to move forward with +POOL, new york city's floating swimming pool of filtered east river water.

connections: +680

TOZZ brings the 90's vibe to the streets with a signature pop-up headlight, boombox, and dirt bike-inspired design.

connections: +320